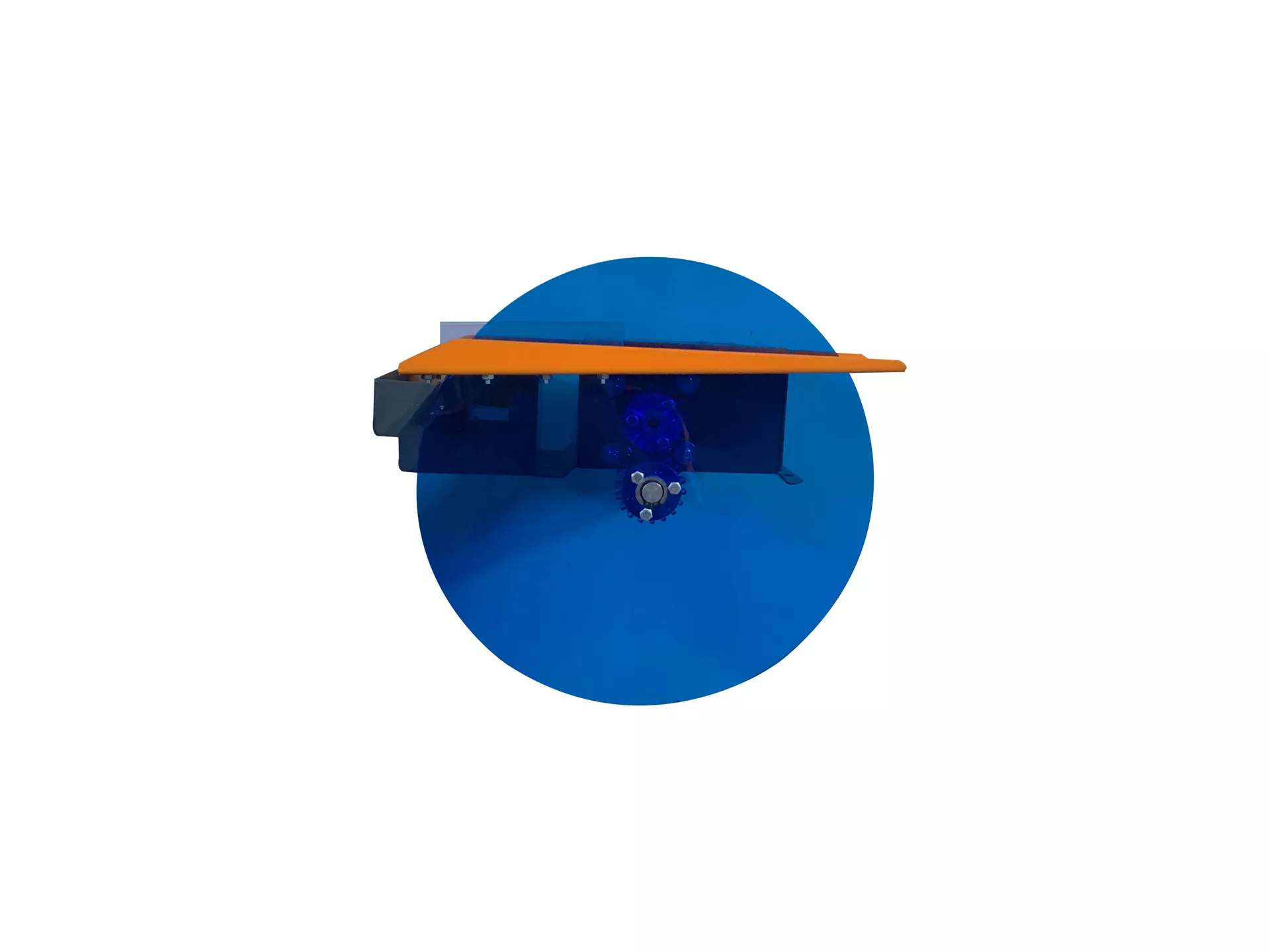

Disc Oil Skimmer

Disc Oil Skimmer

In CNC machines and similar machining centers, slideway oils and other oils that mix into the coolant reservoir are referred to as tramp oil.

According to scientific research, the most critical factor negatively affecting the performance and effective lifespan of coolant fluids is these tramp oils.

Due to their density, these oils accumulate on the surface of the coolant, preventing the lower part from receiving air, which leads to bacterial growth. These bacteria disrupt the delicate balance of the coolant, causing issues such as rust problems, internal machine contamination, inadequate lubrication (resulting in reduced tool life and poor surface quality), unpleasant odors, and smoke.

All these factors lead to significant economic losses and environmental problems in businesses.

Therefore, it is essential to remove these oils from the coolant. Efforts to remove these oils from the coolant using sponges, paper, etc., are neither efficient nor sufficient.

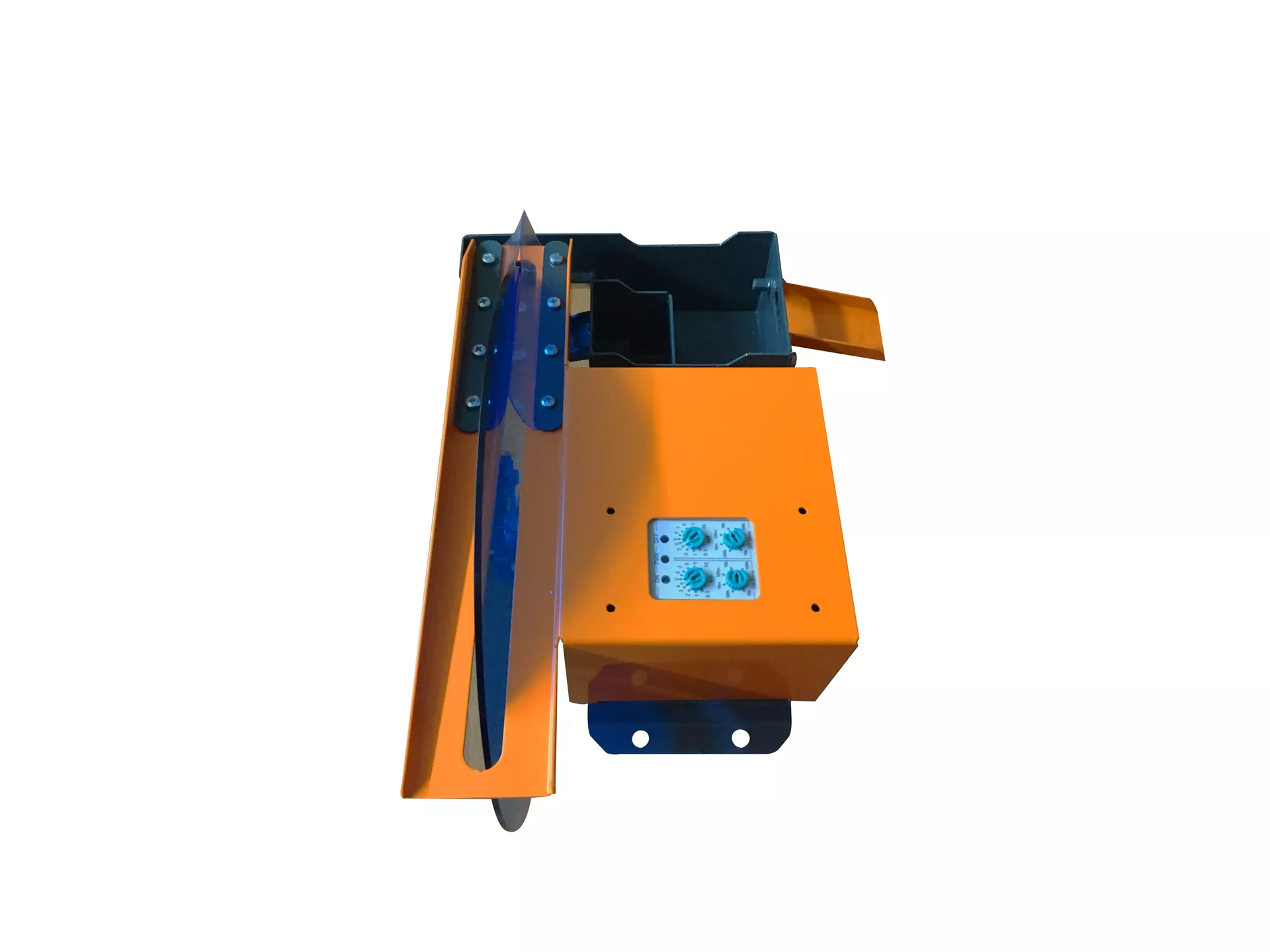

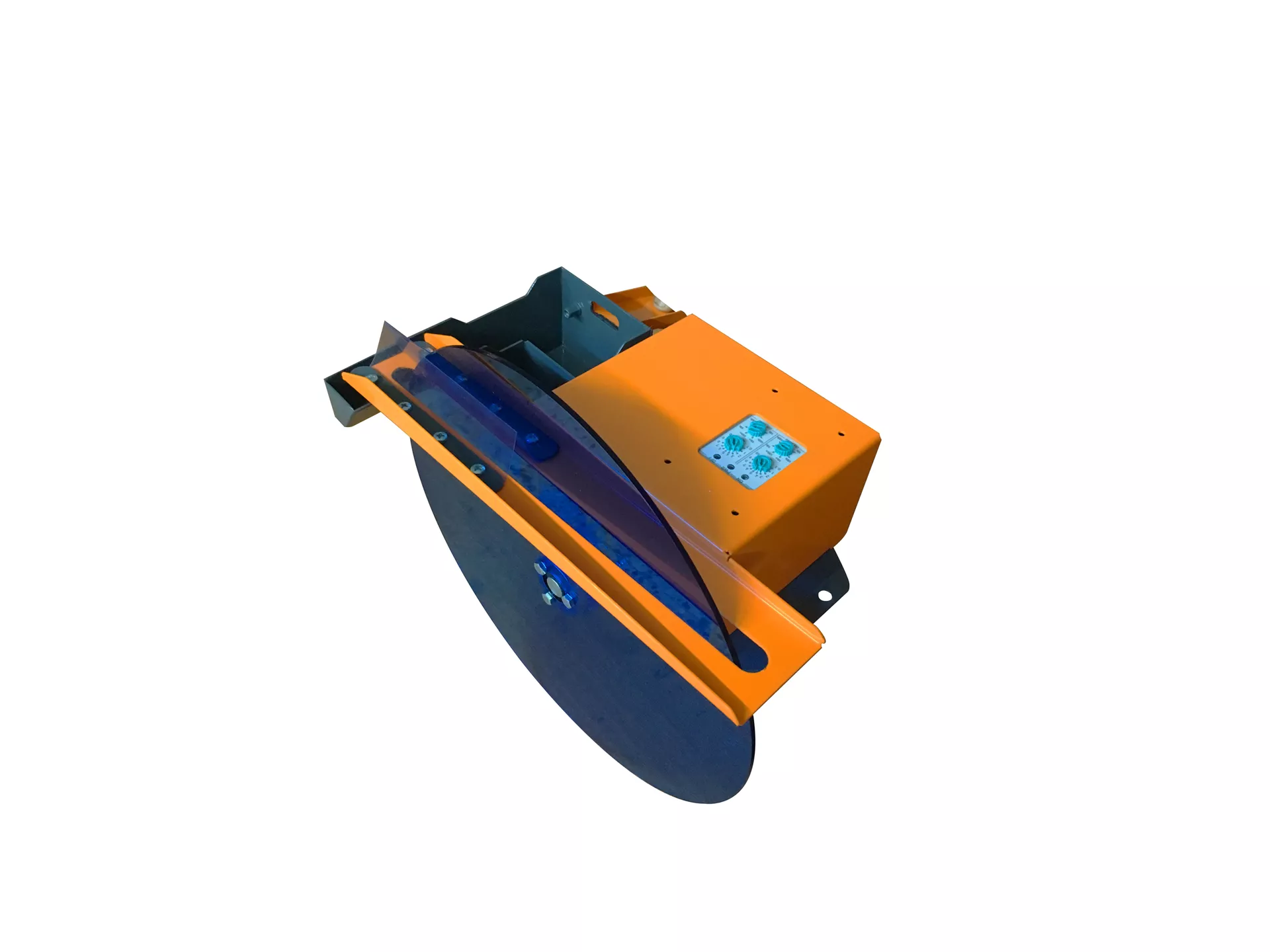

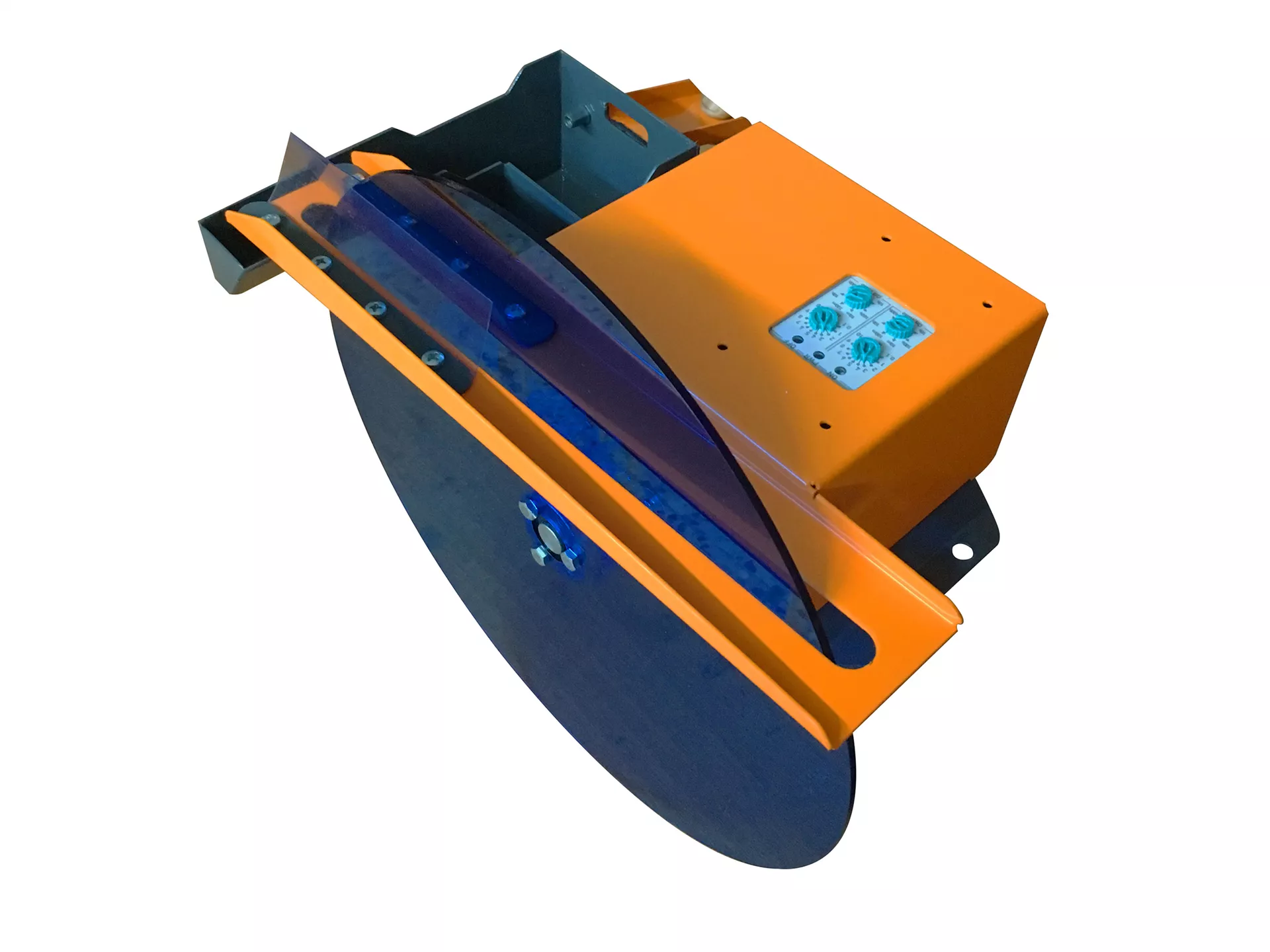

With the Belt Oil Skimmer, all these problems are easily solved.

The Belt Oil Skimmer, which can be easily mounted on the machine tank, skims and removes tramp oils. The collected oil can be readily used in various lubrication operations within the facility.

By extending the effective lifespan of the coolant, achieving higher efficiency from machining centers, and recovering tramp oils, the Belt Oil Skimmer quickly pays for itself.